Technology application

Introduction to the gold-tin melting and sealing process of vacuum eutectic furnace reflow furnace

Release time

2023-03-28

In the field of military and civilian high-reliability electronics, the air tightness of the package is one of the most important reliability indicators. The airtight packaging of gold-tin alloy not only has good sealing and high temperature resistance, but its process also has many advantages: (1) There is no requirement for the thickness of the cover plate, the mechanical strength after sealing and welding is large, and the pressure resistance of the cover plate is large.;

There is no requirement for packaging materials, and airtight packaging can be achieved by valvable alloys, copper, and aluminum.;

The packaging stress is small, as long as the material consistent with the housing is selected as the cover material, the device can withstand the harshest conditions of use.;

It can withstand smoke experiments without any special treatment, so that the device can operate reliably for a long time under corrosive gases.;

(5) Airtight packaging with a certain degree of vacuum can be achieved.Therefore, this process is widely used in many microwave semiconductor devices, integrated circuits and MEMS that require high-reliability ceramic metal structure air tightness.

The gold-tin melting and sealing process of vacuum eutectic reflow furnace has the production characteristics of many varieties. This process can be used to control product quality through program design, and the entire batch can be sealed and welded at the same time, which can greatly improve production efficiency.

Technical research

2.1 Sealing and welding fixture used in the test

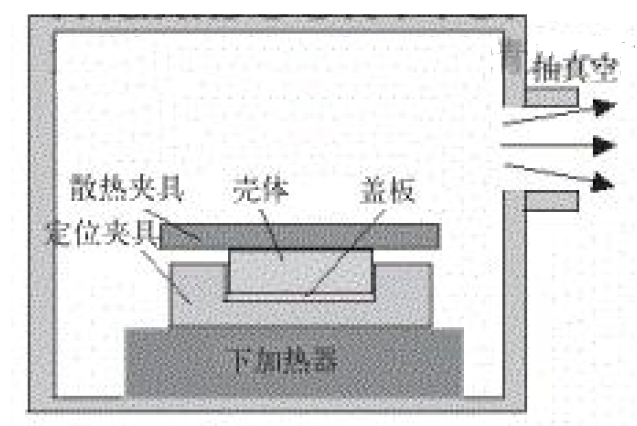

In order to realize the simultaneous sealing and welding of batches and ensure their precise positioning, an inverted array sealing and welding fixture is used. The cover plate, alloy prefabricated sheet, shell, and briquettes are placed in the slots of the tray in turn, and then the tray is placed on the heating plate of the vacuum cavity. After heating to the melting point temperature, eutectic/eutectic is formed, and the shell and the cover plate are sealed and welded together.

2.2 Influencing factors

The influence of the coating quality of the pipe cap on the quality of sealing and welding

If the nickel-plated layer is not dense enough or too thin, certain trace elements (such as Fe) in the substrate can significantly promote the oxidation of the alloy, and the precipitation of Fe can form the initial crystal of FeSn, which affects the flow of AuSn alloy, which in turn affects the air tightness.

Influence of alloy state on welding quality

Before the AuSn alloy is encapsulated, the prefabricated pipe cap with the alloy ring should be stored in a nitrogen cabinet and cleaned with a special cleaning solution or plasma cleaning machine before use to remove a small amount of SnO or SnO2 and other pollutants on the surface of the alloy ring.According to the oxidation mechanism of tin in the AuSn alloy package, the oxygen in the air easily reacts with the tin in the AuSn alloy to form a metal oxide, forming an oxide film on the surface. With the increase of temperature, the thermal movement of the alloy molecules intensifies, and the probability of collision is greatly increased, thereby speeding up the oxidation of tin in the alloy.

At a certain temperature, the oxide can be partially dissolved in the AuSn alloy solution according to the law of distribution. At the same time, due to the concentration difference, the oxide diffuses into the metal solution, thereby hindering the wetting of the liquid solder and the solid base material, and it will also cause the oxide film to enter the weld, resulting in various connection defects, thereby affecting the sealing and welding effect.It is reported that the oxygen content in the alloy must be less than 0.5%, otherwise it is difficult to achieve the ideal sealing effect.

The influence of the surface condition of the sealing surface on the welding quality

It is necessary to ensure that the sealing surface of the shell is clean.When the sealing surface is defiled, the wettability will be very poor. In the state of gold-tin melting, air bubbles will form at the defiled place. When heated and pressurized, the air bubbles will expand and burst, causing air leakage and splashing of gold-tin solder.

Effect of briquetting size on welding quality

Since the heating method is mainly hot plate type, its heat transfer direction is followed by the cover plate, the solder ring, and the housing, and a fixture is added to the housing, which can not only control the thermal conductivity, but also play a role in high temperature and pressure.There are differences in the flatness of the surface of the tube and shell, and the size of the press block is adjusted to make up for the difference in the size of the tube and shell.The pressure loaded on the package cover should be moderate, the pressure is too large to cause the solder to flow out during welding, the pressure is too small, and the air tightness of the welding is poor.

Selection of solder thickness

In order to avoid the outward accumulation of the alloy and facilitate the spread of the solder, the size and thickness of the solder ring must be designed, which determines the yield of the product.

The heating procedure is an important guarantee of the yield

The entire process of gold-tin melting and sealing in a vacuum eutectic reflow oven is divided into three steps: vacuum baking, nitrogen-filled melting and sealing, and rapid cooling.Through the program design, the heating time, heating rate, cooling rate, nitrogen pressure, and vacuum degree are accurately controlled, and the optimal temperature curve is worked out to ensure the yield of the cap.

The melting point of gold-tin alloy is very sensitive to composition near the eutectic temperature. When the weight ratio of gold is greater than 80%, the melting point increases sharply as the gold increases.However, there is often a gold-plated layer when being welded, and the gold in the gold-plated layer will invade the solder during the welding process.Under too thick gold-plated layer, too thin preformed solder pads, and too long welding time, the gold leached into the solder will increase, thereby increasing the melting point.Therefore, the above-mentioned various welding parameters need to be optimized. The temperature applied to the AuSn (80:20) alloy solder during welding should enable the solder to have sufficient fluidity and wettability. Usually, the peak temperature of the vacuum eutectic reflow oven should be selected at about 350℃, the welding time is 2-4min, and the welding yield can reach more than 98%.The specific time mainly depends on the size of the circuit and the solder ring.

conclusion

The key to the gold-tin sealing welding process of vacuum eutectic reflow soldering furnace is the air tightness of the welding.The design of welding equipment and fixtures, the design of process parameters, and the surface state have a greater impact on the air tightness of welding.Due to the characteristics of the AuSn alloy airtight packaging process itself, it has been widely used in high-quality military circuit packaging.On the basis of a large number of research on the technology of gold-tin sealing and welding in vacuum furnaces, through the improvement of tooling molds and the optimization of process parameters, several problems that affect the air tightness during the welding process can be solved. The encapsulated microwave devices, integrated circuits or MESM devices have high air tightness and leakage rate ≤5.0x10-9Pa.m3/s, the one-time pass rate of the product can reach more than 99.5%. This technology has been widely used in mass production of products, and its reliability indicators can pass the GJB128A-96 or GJB548B-2005 quality standard assessment.

This article is derived from the relevant literature published by Liu Yan, who has many years of packaging experience in CLP 55.

Yantai Huachuang Intelligent Equipment Co., Ltd. provides airtight encapsulated vacuum eutectic furnace reflow furnace equipment, and can provide customers with tooling fixtures, vacuum eutectic reflow process curve development, etc.Yantai Huachuang can also provide parallel seam welding machine systems with performance close to imports.

Yantai Huachuang Intelligent Equipment Co., Ltd. has many years of experience in technology and equipment in the military electronics industry. It can customize special tooling and fixtures for customers. At the same time, the equipment has been specially upgraded and optimized for the gold-tin melting and sealing process. For example, the equipment can provide upper and lower heating, controllable temperature rise and fall rate, controllable vacuum degree, positive pressure process, etc.These functions can improve the performance of gold-tin melt-sealed devices.

Previous Page