Technology application

Brief description of the use instructions and technical characteristics of Huachuang intelligent lid opener

Release time

2022-11-14

The capping machine is a non-destructive milling and cutting of the cover plate through a precision milling cutter, which can realize the secondary capping, also known as the capping machine, also known as the capping machine.It is suitable for metal-encapsulated photoelectric devices, thick-film circuits, optical communication devices, quartz crystal oscillators and other devices.Removing the lid is non-destructive.

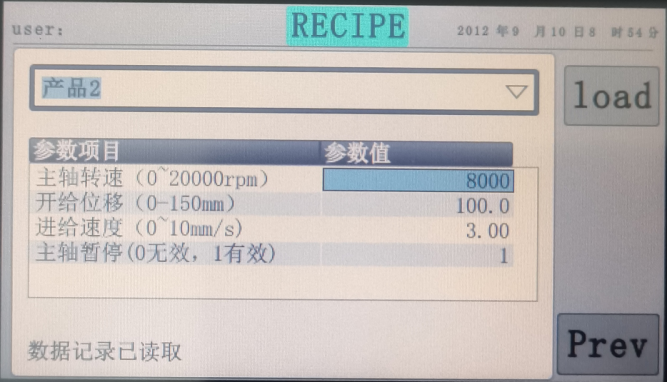

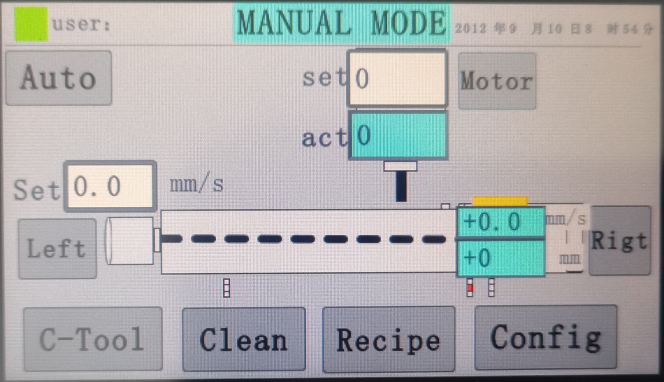

Adopts PLC control, precision servo drive, automatic positioning at startup;

You can set the feed speed of 0.254mm/s and the feed amount of 0.254mm, linear movement, precision cover removal, no vibration, no shock, no damage;

Compact size.Compact structure, suitable for loading into a box in a controlled environment;

Professional TiN-plated high-speed double-thread milling cutter, professional lid removal method, no particulate debris enters the device, will not cause damage to internal components;

The device can be removed multiple times, and the base can be reused multiple times;

Different shapes of devices can be applied by replacing different professional tools;

The size range of the device to be disassembled: the length is from 5mm to 145mm, and the height is 20mm.

Precision cutting depth: 0.010-0.4mm, precision cutting width: 0mm-5mm.

Typical cover removal processing time: about 2-5 minutes (depending on the package form and size of the device), it is easy to replace the tool, and the time to replace different tools: about 5 minutes (typical value);

The product lid is facing down to reduce the height change.The lid maintains contact with the inner wall of the shell and vacuum equipment is added to prevent fine particles from entering the cavity.It is the edge of the lid that is removed, not the shell wall;

PLC control is adopted, and RS232 interface is reserved, which can realize MES docking.

Next Page

Next Page