New Product Release| Yantai Huachuag released 3 new equipment with innovation iteration and upgrade.

Release time

2024-03-14

When the Year of Dragon comes, everything is a new beginning.

In 2024, Yantai Huachuang will set sail, develop and upgrade a number of equipment, which will be exhibited for the first time at the 2024 Laser World of Photonics China in Shanghai.

HC-VS330G Type Getter Activation High Vacuum Reflow Oven System

HC-VS330G is a high vacuum system specially designed for vacuum packaging, which is launched by Yantai Huachuang based on many years of experience in the design, manufacture, process and service of vacuum reflow oven equipment. HC-VS330G can meet the sealing and welding requirements of MEMS devices such as gyroscopes, acceleration sensors and infrared sensors under high vacuum conditions, while achieving thermal and electrical activation of getter under high vacuum environment. The system can be used for scientific research and mass production of devices.

Technical Advantages

1)The equipment is based on the company’s stable and reliable VS330H equipment which has been verified by the market.

2)The top and the bottom are respectively heated by multiple groups of infrared lamps, which can be independently controlled to improve the temperature uniformity of Getter activation and cap welding.

3)The self-designed water-cooling system can improve the cooling efficiency and welding quality under vacuum.

4)The equipment has the function of controllable cooling rate to improve welding stress.

5)The equipment has multi-stage pressure control ability, which can stably maintain a variety of vacuum values for a long time to meet a variety of process requirements.

6)The self-designed water-cooling baffle can ensure that the high temperature radiation heat will not damage the bases and the internal devices of the bases when the getter is activated.

7)The company has a number of senior technical personnel engaged in packaging process with rich experience in fixture design, and they can assist customers to complete fixture design and production.

8)The core components of the equipment are all internationally renowned brands, so as to ensure the long-term stability and reliability of the equipment.

HC-MPVS500 Multilayer Vacuum Reflow Oven

HC-MPVS500 multilayer vacuum reflow oven is the specialized equipment which provides a good process environment for alloy welding of electronic devices by using the principle of vacuum heating, auxiliary formic acid and other technological means. The equipment is widely used in IGBT, high-power LED, high-power semiconductor laser, optical communication semiconductor laser, Lidar devices, TR components, hybrid circuits, discrete devices, MEMS devices, infrared devices and other high-end device packaging. It can realize the perfect welding of high reliability, high vacuum and low cavity of this kind of device.

Technical Advantages

Software system: The interface of software is simple and intuitive. The data and process curve can be freely controlled.

The capability of temperature control: The equipment uses Germany Siemens industrial control system and Siemens temperature measurement module for accurate closed-loop control.

Temperature control method: Independent intellectual property rights. PID adjusts the AEG power regulator automatically for precise temperature control.

Temperature measurement method: There is 1 thermocouple for main control, 1 thermocouple for overtemperature protection, and 2 movable thermocouples.

Cooling method: Air cooling/ water cooling. Water cooling can be used in vacuum sealing process.

Safety function: Overtemperature protection function, water flow and air pressure monitoring function, and formic acid pipeline pressure control.

MES function: With open OPC/ UA protocol, users can simply interconnect with MES system.

Process gas path: There are 2 MFC for precise control. The nitrogen flow rate is 50SLM, and the formic acid flow rate is 30SLM.

HC-AM240 Automatic Parallel Seam Sealing System

Product Introduction

The parallel seam sealing system is the high-performance and specialized equipment for sealing metal and ceramic hermetic bases. By vacuum baking and the sealing process in the glove box, the low water vapor and low oxygen content in the base after sealing can be effectively reduced and maintained, meeting the use requirements of long life, high performance and high reliability of electronic devices in harsh environment. HC-AM240 automatic parallel seam sealing system is a high-performance equipment that adds automatic image recognition and automatic capping functions on the basis of the traditional semi-automatic manual seam sealing machine, so as to meet the increasing requirements of automation, consistency, low labor, high productivity and other aspects in the field of device packaging.

Technical Advantages

1、Welding process with current control mode: Highly integrated control program, optimized to provide the best welding results.

2、Programmable electrode force: The device allows users to program for settings while optimizing force and energy for superior sealing results. Multi-point force calibration ensures precise force control and consistency.

3、High frequency welding power supply with double pulse: The machine is equipped with a “warm-up” pulse to prevent temperature shock. The high frequency and narrow pulse width realize low temperature welding, and improve the sealing quality and yield. It is especially suitable for the sealing of ceramic devices which are easy to burst.

4、Automatic track change function of electrode: By using software to realize the automatic adjustment of the electrode track, the wear of the electrode contact surface is reduced, the width of contact surface is fully utilized, and the service life of the electrode is extended.

5、The weld pulse can be adjusted: The energy at the corner of the sealing base can be adjusted separately, which can effectively reduce the probability of leakage at the corner of the base.

6、The rollback function of electrode: The rollback function of electrode is suitable for sealing lightweight base, which can effectively prevent the electrode from “sticking” base.

7、The function of welding and stop-welding: The parallel seam sealing machine communicates with the glove box in real time to confirm that the gas purity in the glove box meets the set requirements before welding is allowed, which can effectively avoid the products failure caused by the substandard water vapor in the glove box. Welding files are stored without limitation.

8、Sealing from the middle to corner: It is a very effective sealing mode for large size bases to seal from the middle to the corner.

9、Advanced cover plate feeding method: The magazine type cover plate feeding method effectively improves the feeding efficiency and accuracy.

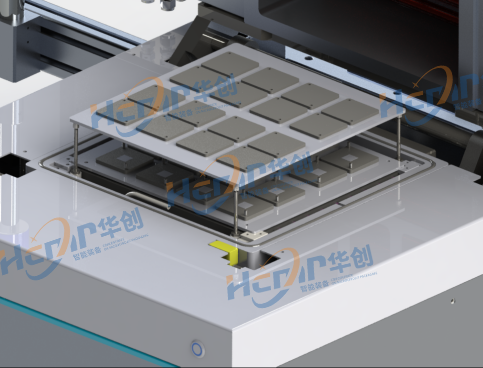

10、Array type sample fixture: Design sample fixture tray according to customer’s samples.

11、Professionally designed glove box: Special glove box customized according to the use habits and process specifications of military electronics industry and optoelectronics industry, with simple use, stability and data traceability.

Yantai Huachuang always adheres to the innovative concept of equal emphasis on innovation and creation, parallel process and R&D, and upholds professional, efficient, and service-oriented service attitude.

In addition to the above newly released equipment, there are VS-330H vacuum reflow oven, HC-DL145 De-lidder, PIND and other equipment appeared at the exhibition.

We sincerely invite you to visit our booth and have an in-depth discussion with our professional team for cooperation opportunities together! You will be warmly welcomed by senior sales consultants and technical experts to provide you with comprehensive answers.

Booth No.: W3-3260. See you in Shanghai!

Related information