Products

SM200MAT Parallel Seam Sealing Machine

The parallel seam sealing system is the high performance and specialized equipment for sealing metal and ceramic hermetic base. By vacuum baking and the sealing process in the glove box, the low water vapor and low oxygen content in the base after sealing can be effectively reduced and maintained, meeting the use requirements of long life, high performance and high reliability of electronic devices in harsh environments.

Classification:

Arrayed Parallel Seam Sealing Machine

Key words:

- Product Description

- Technical Parameters

- Technical Advantage

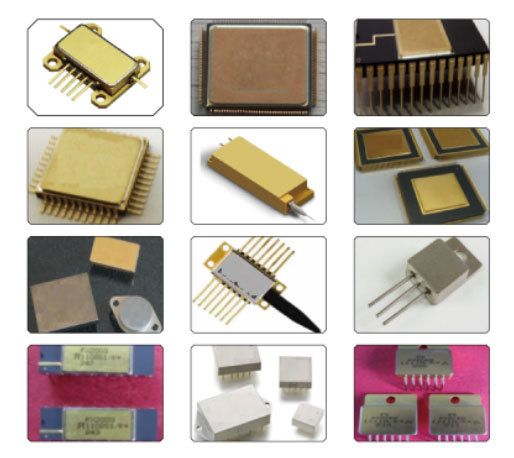

- Typical Welding Products

-

The parallel seam sealing system is the high performance and specialized equipment for sealing metal and ceramic hermetic base. By vacuum baking and the sealing process in the glove box, the low water vapor and low oxygen content in the base after sealing can be effectively reduced and maintained, meeting the use requirements of long life, high performance and high reliability of electronic devices in harsh environments.

-

Technical Parameters of Seam Sealing Machine

Drag and drop the dropdown bar on the right to view more parameters

Specification/Model

HC-SM200

HC-SM200MAT

Lidding method

Manual lidding

Manual lidding

Welding mode

Single

Single or matrix

Shape of base

Square + Round

Square (single or matrix)+Round (single)

Size of base

3mm-200mm(Other sizes are optional)

3mm-200mm(Other sizes are optional)

Repeat positioning accuracy

±0.02mm

±0.02mm

Max welding speed

50mm/s

50mm/s

Rotation angle

360°

360°

Frequency of power feedback

8kHz(Other optional)

8kHz(Other optional)

Pulse width

0.125ms-120ms

0.125ms-120ms

Max welding current

3kA

3kA

Max welding pressure

5000g

5000g

Technical Parameters of Glove Box

Drag and drop the dropdown bar on the right to view more parameters

Specification/Model

HC-GB1200

Glove box body

Internal size of box

1200mm*1000mm*950mm(L*W*H)

External size of box

2300mm *1000mm *1900mm(L*W*H)

Leakage rate

<0.001vol%/h,comply with ISO 10648-2 international standard

Vacuum oven

Size

500mm*320mm*330mm(L*W*H)

Oven door

Touch screen operation, automatic cylinder locking+ logical interlock+ anti-misoperation design

Heating method

4 layers heating plate, 3 layers samples area, 75mm layer height

Temperature control method

Gradient temperature control. The temperature, time and cycle-index can be set through the touch screen

Temperature range

Normal temperature-200℃(300℃ is optional)

Temperature accuracy

±1℃

Ultimate vacuum

≤100mtorr

Antechamber

Size

500mm*320mm*330mm(L*W*H)

Antechamber door

Touch screen operation, automatic cylinder locking+ logical interlock+ anti-misoperation design

Sontrol system

PLC control

Siemens PLC, colorful dynamic touch screen, password protection

Data record

Water and oxygen content, pressure, and temperature data can be viewed

Optional spare parts

Moisture analyser

Brand: Michel, ceramic humidity transmitter, PLC display

Range:-100~+20℃ dew point(0-1000PPM)

Accuracy: ± 2% dew pointOxygen analyser

Brand: GE, electrochemical sensor, independent display, PLC display

Range:0-10 、20 、50 、100 、200 、500 、1000ppm(special electrochemical cell for trace oxygen)

Accuracy: ±2% FS(0.2PPM)Vacuum pump

Select according to customer needs:Edwards RV12、nXDS 10i,Baosi GSP3, etc.

Nitrogen purification system

5KG molecular sieve、5KG copper catalyst

-

Welding process with current control mode: Highly integrated control program, optimized to provide the best welding results.

Programmable electrode force: The device allows users to program for settings while optimizing force and energy for superior sealing results. Multi-point force calibration ensures precise force control and consistency.

High frequency welding power supply with double pulse: The machine is equipped with a “warm-up” pulse to prevent temperature shock. The high frequency and narrow pulse width realize low temperature welding, and improve the sealing quality and yield. It is especially suitable for the sealing of ceramic devices which are easy to burst.

Automatic track change function of electrode: By using software to realize the automatic adjustment of the electrode track, the wear of the electrode contact surface is reduced, the width of contact surface is fully utilized, and the service life of the electrode is extended.

The weld pulse can be adjusted: The energy at the corner of the sealing base can be adjusted separately, which can effectively reduce the probability of leakage at the corner of the base.

The rollback function of electrode: The rollback function of electrode is suitable for sealing lightweight base, which can effectively prevent the electrode from “sticking” base.

The function of welding and stop-welding: The parallel seam sealing machine communicates with the glove box in real time to confirm that the gas purity in the glove box meets the set requirements before welding is allowed, which can effectively avoid the products failure caused by the substandard water vapor in the glove box. Welding files are stored without limitation.

Sealing from the middle to corner: It is a very effective sealing mode for large size tubes to seal from the middle to the corner.

-

Related Products

Message consultation